✔ Complete Robust & Sturdy construction for long lasting performance.

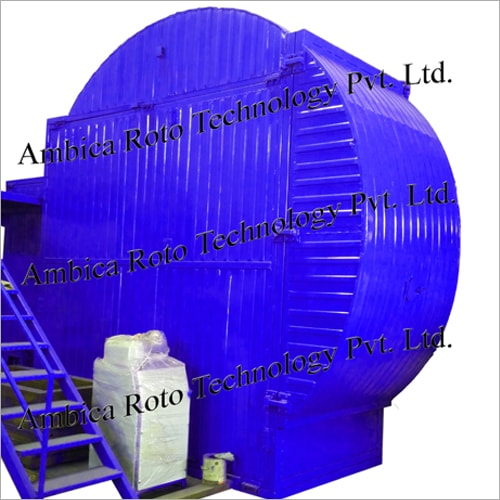

✔ Movable Oven chamber.

✔ To minimize the heat losses with efficient Rock wool Insulation saves the heat energy.

✔ Powder coated Electrical panels with dust proof construction with PLC & HMI.

✔ Auto reversal facility for all major & minor axis are provided with timing circuit.

✔ Complete wiring as per color code and specifications recommended as per relevant.

✔ All necessary safety features and controls are provided. Superior grade paint with standard five stage process. Timing circuit for 2nd layer and 3rd layer feeding of material is also provided.

✔ Lift for powder feeding.